The T R I Group

Helping The T R I Group achieve Zero Waste to Landfill certification and increase recycling rates...

Read MoreWe provide an independent Zero Waste to Landfill Certification service

The benefits of earning Zero Waste to Landfill Certification include:

We are offering a new service – ‘Zero Avoidable Waste to Landfill Certification’.

Our new certification tier allows for small amounts of a business’s waste to go to landfill when there was no other option for particular waste streams.

It is hoped that this new certification tier will communicate transparency and will therefore prevent businesses from being accused of greenwashing.

The certificate for this tier will detail the percentage amount of ‘Zero Avoidable Waste to Landfill’ and we will also provide a ‘Zero Avoidable Waste to Landfill’ logo for marketing purposes.

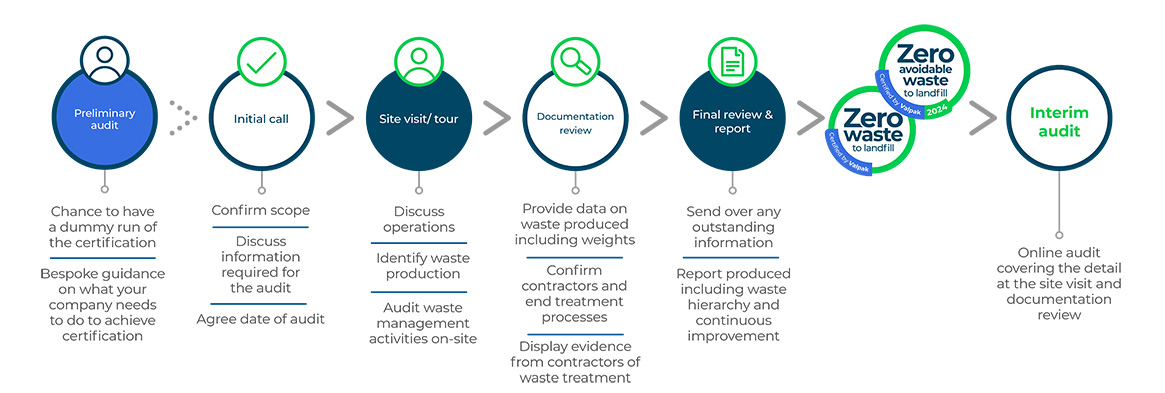

Valpak provides independent certification of an organisation’s zero waste to landfill achievement by performing a site audit and a review of documentation. When implementing a Zero Waste to Landfill strategy it is not enough to simply ask your waste contractor to stop sending your waste landfill. You need to have a full audit trail to demonstrate that your material is being treated correctly and to prove that nothing ends up in landfill.

Valpak provides independent certification of an organisation’s Zero Waste to Landfill achievement by performing a site audit and a review of documentation.

Valpak’s expert Zero Waste to Landfill Team has extensive knowledge of waste and environmental auditing. Working alongside our Rio Sustainability Platform Team, who help organisations achieve Zero Waste to Landfill Certification, we advise on the latest treatment processes.

Every business is different. While some customers are just looking for independent assessment of their work; others need help to get zero waste to landfill off the ground.

Our friendly team can help with:

This is a common problem. Many companies think they may have achieved zero waste to landfill but aren’t completely sure.

If you are in this situation, remember that a clear audit trail needs to be in place in order to demonstrate where your waste goes and what happens to it. Your contractors should be able to report on the volumes of waste they are collecting from your business; however, marrying multiple reports into one concise set of figures can prove to be difficult.

If in doubt, ask for help!

It is a process where all the waste materials and products generated by an organisation are diverted away from landfill to treatment processes further up the waste hierarchy.

UK legislation supports the move away from landfill. The Waste Framework Directive means that UK businesses and organisations should apply the waste hierarchy to their activities, while Scotland has banned the disposal of municipal biodegradable waste to landfill.

Our new certification tier allows for small amounts of a business’s waste to go to landfill when there was no other option for particular waste streams.

The UK legislation supports the move away from landfill. The Waste Framework Directive means that UK businesses and organisations should apply the waste hierarchy to their activities, while Scotland has banned the disposal of municipal biodegradable waste to landfill.

Timescales vary. Some businesses have straightforward operations with limited waste streams; others involve multiple sites and partners, and a high number of waste products. Sometimes different sites will manage waste in different ways.

The first step is to assess your waste streams and disposal routes. With this information, you will be able to decide the level of support needed.

Your business will need to be able to demonstrate that it is diverting all waste from landfill.

The ideal scenario is to first try and prevent as much waste from being produced as possible. Secondly, unavoidable waste should be reused or recycled. Where this isn’t possible, the remaining waste would go for recovery (e.g. Energy from waste incineration).

You will need to collect information on the weight of each waste material and ask contractors to provide information on the treatment processes and end markets.

It is important to remember that even though two facilities may perform the same process, they may send separated waste materials to different end-treatment facilities. Waste may ultimately end up in recycling, recovery, or landfill markets.

It is the business’s responsibility to apply the waste hierarchy to any waste created at its sites. It must also try to prevent waste from going to landfill.

The organisation should ensure that waste is separated by type before it is collected, have signs in place to ensure that staff do not cause contamination and select contractors that will be proactive in helping the business to meet its target.

Under UK waste legislation, contractors are responsible for applying these conditions if they transfer your business’s waste to a third party.

This is any evidence that is provided by your waste contractor that should specify more than just the waste that was diverted from landfill but information on whether it was reused, recycled, or recovered, where this has taken place (location if they won’t specify further) and if recycled what into.

With recovered waste; i.e. Energy from waste incineration, the contractor needs to confirm what happens to the incinerator bottom ash (IBA). This can be provided in various forms including an email or process flow document.

Like all the other waste information this needs to be updated annually ahead of the audit.

Yes! Your contractor may also be investigating new routes to achieve zero waste to landfill.

If they resist, explain that it is also in their interest to move away from landfill.

To find out more, contact us today.

We’re thrilled that Euroclad is to be the first within the Kingspan group of companies to earn third party Zero Waste to Landfill Certification! We’d like to give a huge thank you to Valpak for guiding us through the process. Their clear introductory information made everything seamless, and the comprehensive report (with constructive recommendations!) was invaluable. We’re excited to continue working together in future and driving sustainability forward!

Our experience with Valpak's Zero Waste to Landfill certification service has been outstanding. From the initial audit to ongoing support, Valpak has been instrumental in guiding us towards achieving our sustainability goals. The audit process was helpful and enlightening, offering insightful recommendations on how we can improve our waste management processes, overall awareness, and practices on-site. What sets Valpak apart is professionalism and kindness.

Valpak's Zero Waste to Landfill Certification service has helped us transform our waste management practices. The comprehensive audit laid the groundwork for significant improvements, guiding us to implement a robust waste data recording system and ensuring compliance with all necessary waste handling regulations. Achieving ZWTL Certification in May 2024 was a milestone for us, reflecting our commitment to sustainability and our continuous pursuit of operational excellence.

Our comprehension of our environmental duties has been greatly enhanced by Valpak’s Zero Waste to Landfill certification. We have learned a great deal about the effects of our waste management methods on the environment by implementing Valpak’s recommendations. Certification has bolstered our broader commitment to environmental control by raising awareness of the significance of reducing, reusing, and recycling throughout our operations.

With Valpak’s support and advice, we not only managed to achieve Zero Waste to Landfill certification for 2019, but also managed to reduce our carbon footprint and gain increased value from some of our waste materials. The business opportunities that have arisen from this recognition are a bonus.

We found the whole process of this certification excellent and thoroughly carried out. Valpak's auditors were very knowledgeable and helpful throughout the process for each group company. This journey to ZW2L certification has allowed us to identify areas of improvement and cast a more thorough eye on our recyclable material. Certification allows us to showcase our commitment to sending no textiles to landfill and fits in well with our own ESG goals. We would highly recommend Valpak.